Clay bin and plaster batt

A full tub of dried, crushed clay ready to recycle. Next to it, a large slab of plaster called a batt, which will absorb extra water in the clay.

Adding moldy slip to sour the clay.

In the pail, we see some slip I mixed up about three years ago. Notice the blue color under the surface of the slip - this is mold. Adding a few scoops of this to the clay will encourage mold growth, like a sourdough starter or yeast into a dough. This process, called souring, increases plasticity to the clay. Also notice how thick and creamy the slip is, even after having sat for months without stirring. this is due to the addition of bentonite, a clay body that is a strong deflocculant, which helps keep particle in suspension. Add enough, and the slip will turn into a gel.

Adding vinegar and water to the dry clay.

Vinegar is a flocculant - meaning it encourages clay particles to fall out of suspension. We want this, to settle the finer particles quickly, in order that the particles don't settle in strata according to size after mixing the clay. The sour slip I added contains bentonite, which will encourage suspensions, so it's important that I add vinegar if I also add a souring agent. About 1% vinegar to weight of clay is needed, but you can estimate and it will work fine.

Watered clay.

Note all the air bubbles rising. You will also get floating bits or impurities which you can scoop out at this point.

Clay settled out of suspension.

This is before I stirred the clay and water mix - but notice that the chunks of clay have dissolved into something resembling a silt deposit. I will now stir the clay with my hands, checking for lumps of harder clay to break apart or impurities, and allowing the water greater access to the depths of the bucket.

Mud.

The clay particles have been freed of most of their bonds, and now align themselves at right angles to the other clay particles nearby, thus destroying plasticity. We will need to knead the clay back into layers of particles lying next to each other to regain plasticity.

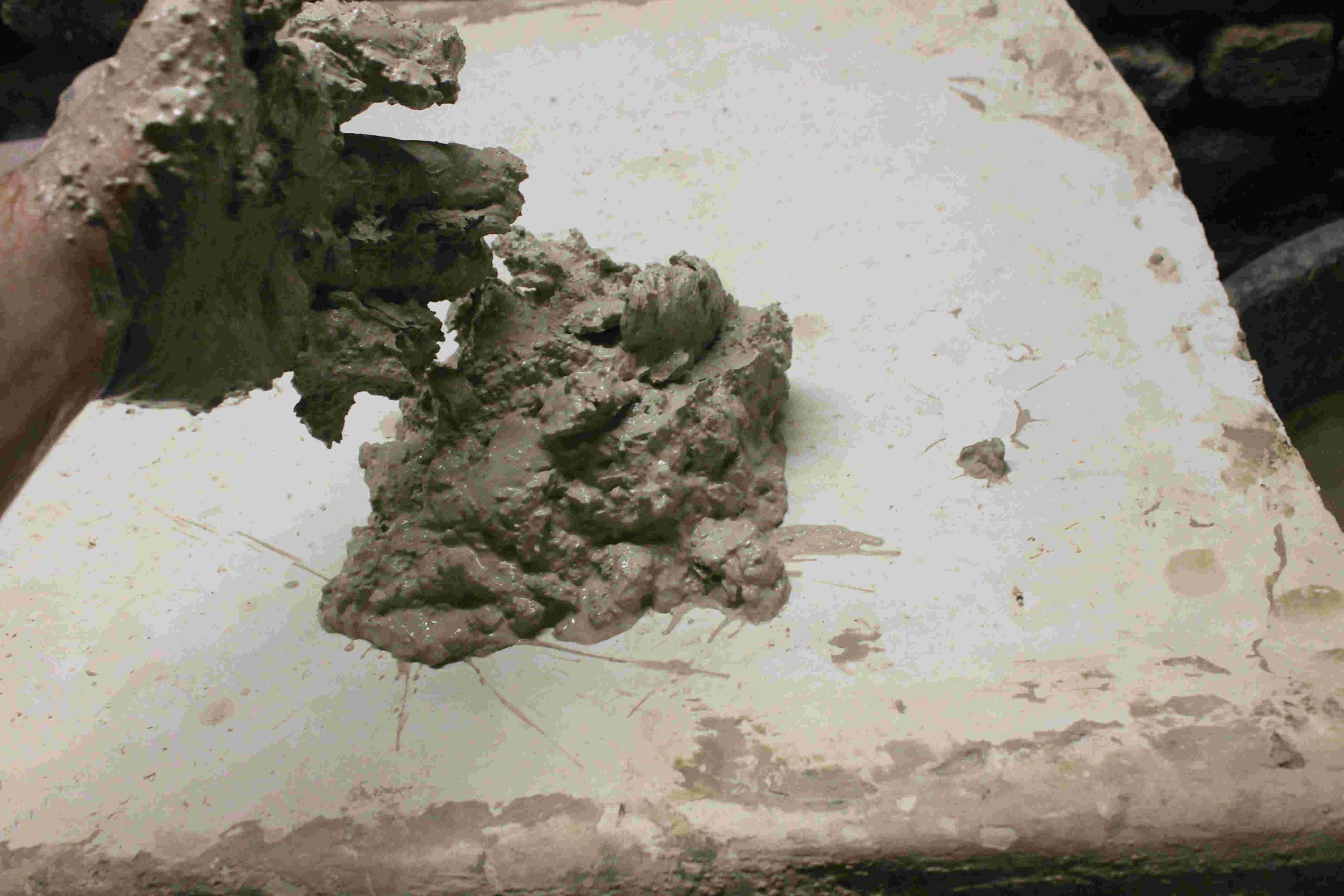

Clay muck laid out on the batt.

The clay will dewater by the action of the plaster batt sucking moisture out through the bottom of the clay. This will mean that the bottom will dry first, so it is important to keep an eye on how fast it's drying.

Turning the clay.

At a certain point, the clay will be dry enough on the bottom to where you can peel the mass cleanly away from the plaster batt. The clay above the bottom will still be very wet, however, so you should flip the mass over. It's tricky to do it all in one piece; I usually do it in sections.

Almost ready to wedge and knead.

The clay in this picture has been flipped and now I am just waiting until the perfect moisture content to wedge and knead it. I wedge mine on the softer side, and through hard-won experience I have learned to not let the clay sit on the batt a moment longer than I like it. with a dry batt, the dewatering process takes about a day and a half to two and a half days.